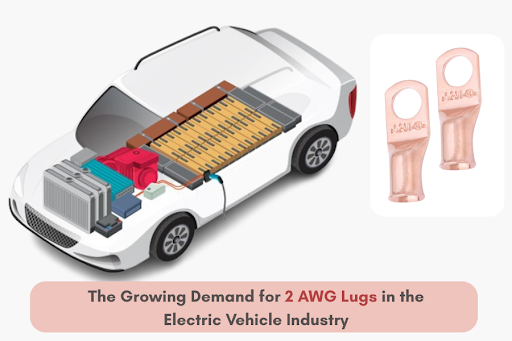

The EV revolution has arrived and isn’t going to slow down anytime soon. High-performance, high-current connections are becoming more and more necessary for everything from personal vehicles and two-wheelers to commercial delivery vans and off-grid EV conversions.

And while the battery pack, charging speed, and motor get all the attention, there’s one component quietly doing the heavy lifting behind the scenes: the 2 AWG cable lugs.

As electric vehicles become more sophisticated and power-hungry, the need for 2 gauge lugs that deliver safe, reliable performance has never been greater. In this post, we’ll explore why 2 AWG lugs are becoming a staple in the EV industry and what makes them essential for powering the future.

Why 2 AWG Is The Sweet Spot For EV Wiring

For high-current DC power transfer, 2 AWG (also known as 2 gauge) cable is the preferred size. Though it is flexible and manageable enough to be installed in confined spaces, such as under EV hoods, close to battery packs, or inside BMS enclosures, it is thick enough to support heavy loads, frequently exceeding 150–200 amps.

In EV applications, you’ll commonly find 2 AWG wire and matching lugs used for:

- Battery-to-controller connections

- Inverter wiring

- Charging system hookups

- DC distribution between modules

- Upgraded lithium battery packs in retrofitted vehicles

And with so much current moving across these lines, your 2 AWG cable lugs aren’t just accessories; they’re critical.

What Makes A Quality 2 Gauge Lug Essential?

Electric vehicles demand consistency, safety, and durability. A low-quality connection point can cause:

- Voltage drops

- Heat build-up

- System inefficiency

- Even electrical failure

Here’s what a premium 2 AWG cable lugs like those from Selterm brings to the table:

1. Pure Copper Construction

Selterm’s lugs are made from 99.9% electrolytic copper, offering superior conductivity. That means more power gets to where it needs to go, with less resistance and heat.

2. Seamless Barrel Design

A seamless lug barrel ensures stronger crimping without weak points. This is especially important in EVs, where road vibrations and temperature swings can wear down poorly crimped terminals.

3. Stud Size Options

EV setups vary. From BMS terminals to fuse blocks, you need lugs that fit your hardware. Selterm offers multiple stud sizes for its 2 AWG cable lugs, so you always get a clean, secure fit.

Why The EV Industry Is Driving Demand

Here’s why more EV builders, both OEMs and DIYers, are turning to 2 gauge lugs:

1. Higher Battery Voltages And Current Loads

Modern EVs are running at 48V, 72V, or even higher, and drawing hundreds of amps. The days of 10-gauge or 12-gauge wiring are over. Reliable lugs are needed to safely manage the surge.

2. DIY Conversions Are On The Rise

Classic cars, motorcycles, and off-grid vehicles are being converted to electric by an expanding group of EV enthusiasts. They require high-quality, easily installable, reasonably priced 2 AWG cable lugs.

3. Commercial Fleets Need Reliability

From delivery vans to airport shuttles, EV fleets operate daily in tough environments. Loose or corroded connections? Not an option. Secure 2 AWG cable lugs become a long-term investment in uptime.

Installation Matters Too

It’s not just the lug, it’s how you install it. Here are a few quick reminders when working with 2 AWG cable:

- Strip cleanly — Remove just enough insulation to fully seat the wire

- Crimp correctly — Use a heavy-duty crimper designed for 2 AWG

- Seal the connection — Apply heat shrink tubing (preferably dual wall) to protect against moisture and vibration

- Double-check fit — Ensure the lug sits flat and firm against the stud

- The cleaner the install, the longer your system lasts.

A Step Toward Cleaner Tech

Every EV that hits the road is part of the movement toward greener, more sustainable energy use. But that transformation also depends on infrastructure and components that perform day in and day out.

It’s not just about innovation. It’s about execution.

And that’s where well-made 2 gauge lugs play a surprising but critical role. They assist in making sure that every electron travels to its destination in a safe, effective, and reliable manner, from the charging port to the inverter.

Why Choose Selterm 2 AWG Lugs?

Selterm’s 2 AWG bare copper lugs are trusted across the EV, solar, and marine industries for a reason:

- Made from high-conductivity copper

- UL and CUL certified for safety and performance

- Seamless design for stronger crimps

- Available in multiple stud sizes and pack quantities

- Ships fast, priced right, and built to last

Whether you’re an EV conversion hobbyist, a fleet installer, or an OEM, Selterm’s lugs give you one less thing to worry about.

Final Thoughts

The EV industry is moving fast and smart builders are choosing components that keep up. As battery tech improves and current loads increase, 2 AWG cable lugs are quickly becoming the new standard for efficient, secure power delivery.

It’s a small part with a big role in the future of transportation. Choose wisely. Crimp confidently. And drive forward, powered by precision.